REFURBISHMENT

Barcon offers complete refurbishment services for production equipment used in the oil and gas industry. With various in-house testing capabilities, such as nondestructive testing, destructive testing, pressure testing, and registration for repairs with The National Board, Barcon has the ability to re-certify your equipment. We will analyze the unit for safety and operability to ensure that the equipment is functional for many more years of service. Refurbishment is an excellent economic solution to drive down capital expenditures of new facilities.

FIRE TUBE INSPECTION

• Verify leak free welds

• Confirm proper sizing

TESTING

• NDE Services

• Pressure and leak testing of all components

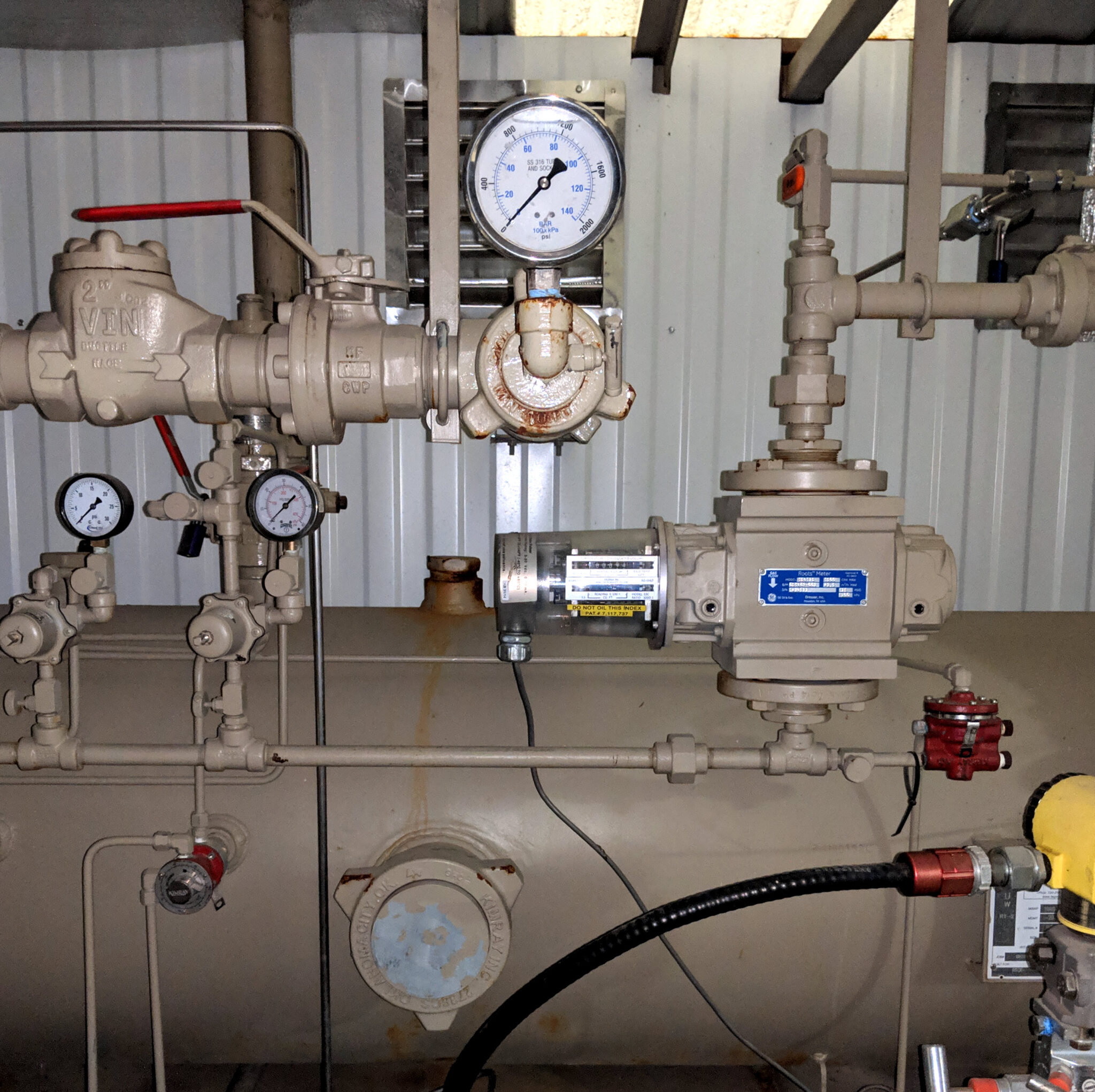

PROCESS PIPING INSPECTION

• Inspect and/or upgrade welded and threaded piping assemblies

SAFETY EQUIPMENT INSPECTION

• Inspect/Repair/Test relief valves, ESD valves, and chokes

FUEL GAS / INSTRUMENTATION INSPECTION

• Inspect and/or upgrade instrumentation

COIL INSPECTION

• Verify wall thickness

• Verify MAWP via calculations and testing

BURNER INSPECTION

• Inspect and/or upgrade burner system

SEPARATOR INSPECTION

• Confirm conformance to ASME Sect. VIII

• Verify MAWP via calculations and testing

• Flush and clean internals